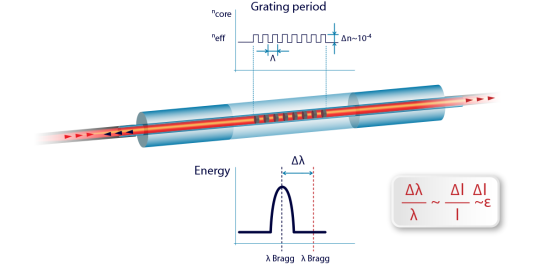

What is a Bragg grating?

A Bragg grating fiber is a microstructure of a few millimeters, a kind of marking that can be inscribed on the core of a standard telecommunication type fiber. Light is reflected by illuminating the fiber transversely with a UV laser beam. The marking produces an interference pattern in the core, which will cause a permanent change in the physical characteristics of the silica matrix. This change consists of a periodic modulation of the refractive index of the core that creates a resonant structure.

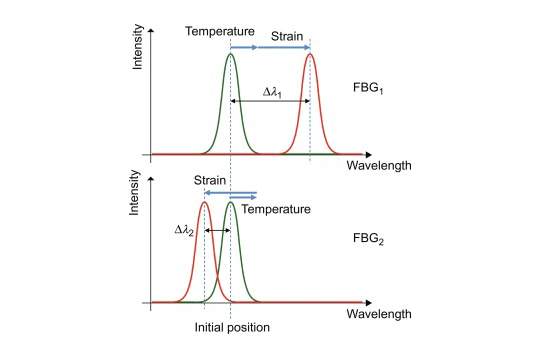

Strain measurement by fiber optic sensors

The use of fiber optic sensor technology for strain measurement is particularly well suited. Unlike conventional strain gauge technologies (wire strain gauges, electrical strain gauges, etc.) which usually require a "Wheatstone bridge" type assembly, fiber optic sensors of the "Bragg grating" type can be directly and easily implemented on the elements undergoing stress. The Bragg grating corresponding to a very small part (from 1 to a few millimeters) of an optical fiber made sensitive, it is possible to arrange a multitude of sensors or "strain gauges" on a single optical fiber. Moreover, an interrogation unit is able to monitor up to 120 measurement points (or many more by using an optical multiplexing system) distributed over one or more optical fibers.

Perfectly optimized and fully adaptive

This Bragg Grating strain measurement technology has many advantages:

- High performance measurements

- Total immunity to electromagnetic interferences

- High robustness and reliability in environments subject to strong vibration and shock

- Very low losses and transport of measurements over very long distances (hundreds of metres to several kilometres)

- Compliance with explosion-proof standards and ATEX directives

- Compact and very low-intrusive

- Distributed measurements and networking of a large number of individually addressable sensors

Perfectly optimized and fully adaptive, the wide range of Bragg Grating sensors and interrogators developed by LGS by Texys allows the configuration to be adjusted to different uses to ensure cost and performance optimization.

Test, validation, industrial and structure monitoring

Application cases for Bragg Grating sensors :

- Monitoring of structures (historical monuments, cathedrals, castles, etc.)

- Industrial monitoring (gantries and overhead cranes, petrochemical tanks, storage equipment, silos, rolling mills...)

- Civil engineering instrumentation (bridges, viaducts, tunnels, underground parking, mines...)

- Offshore monitoring (oil platforms, wind turbines, forge, extraction...)

- Structural monitoring (dams, dykes, road networks, rail networks, distribution networks, pipelines, aqueducts, containment systems...)

- Aeronautical and naval instrumentation (structure, hulls, wings, kerosene tanks, blades, propellers, turbines...)